Digital Catapult, the UK authority on advanced digital technology, has today announced an ambitious new project, the Logistics Living Lab, to cut the carbon emissions of empty and near-empty delivery trucks on the road. The project comes as road freight transportation and removal services produced 11.5 million metric tons of carbon dioxide emissions in 2020, threatening the progress in the UK to reach net zero by 2050.

Freight accounts for 31% of all UK transport CO2 emissions, and these emissions are the main driver of climate related risks including climate change and extreme weather.

This is where the Logistics Living Lab will make a difference, by leveraging emerging technologies including distributed ledger technology (DLT) and the internet of things (IoT) to reduce the number of empty trucks releasing pollutants into the atmosphere on roads across the country.

The Logistics Living Lab will see the development of a shared digital infrastructure for more intelligent management of vehicle slot filling, routing, and tracking to allow competing logistics providers to safely share information available truck space across their collective fleets, without the need for a single party needing full control or visibility of the whole system.

The infrastructure, underpinned by DLT, aims to deliver greater coordination across the logistics sector without compromises to commercial sensitivity and security of data, while enabling greater operational efficiency.

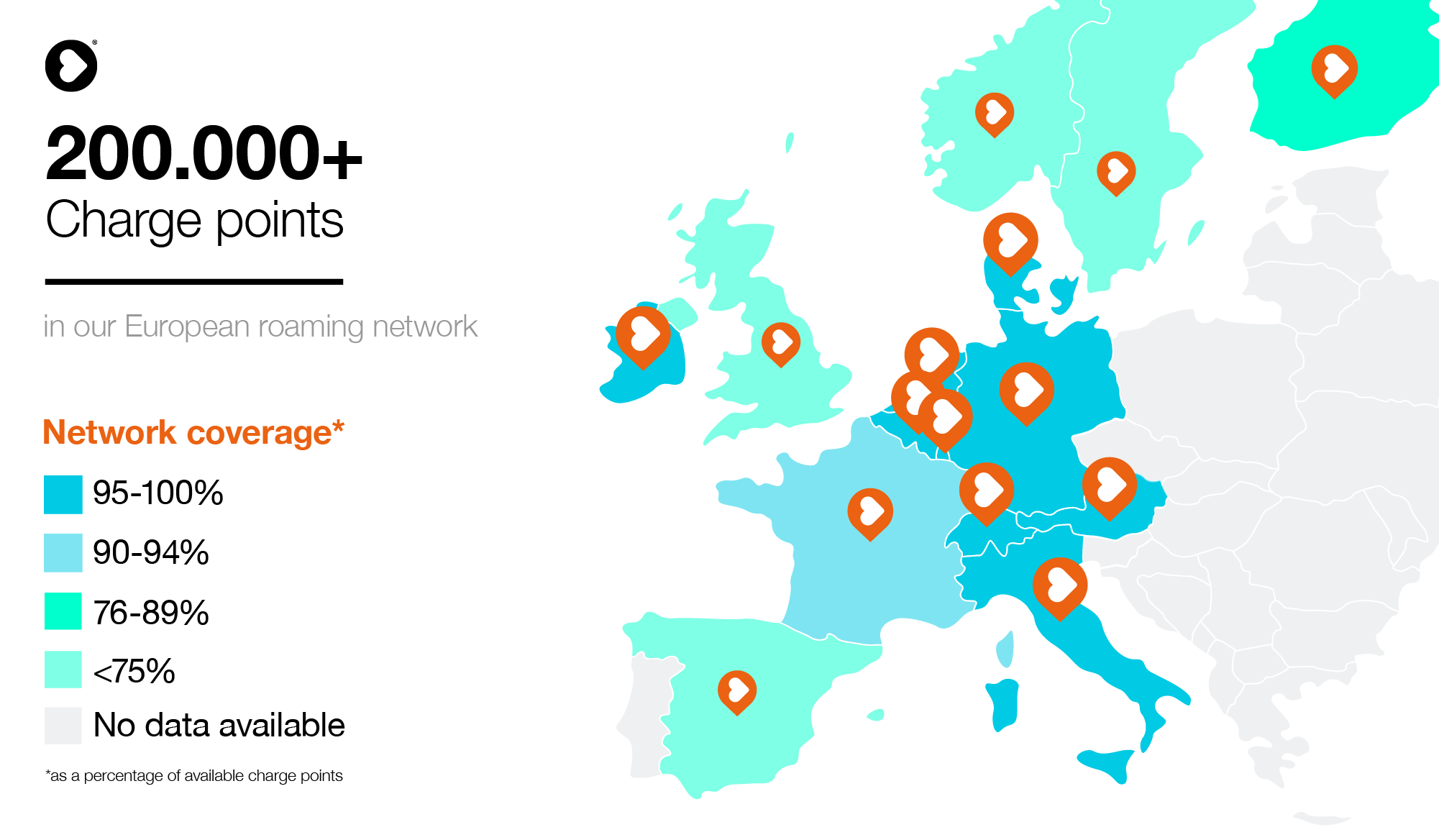

The project brings together five leading digital innovators including Vodafone Digital Asset Broker, Microsoft, Yusen Logistics, Fuuse, and Parity Technologies. Digital Catapult are leading the consortium of companies, with a shared goal of reducing emissions and increasing capacity utilisation, as it looks to encourage broader adoption of sustainable innovation in business and industry. The project will run until September 2024.

The Logistics Living Lab project is part of Digital Catapult’s Made Smarter Innovation Digital Supply Chain Hub which aims to make supply chains more efficient, resilient and sustainable by developing and promoting the adoption of advanced digital technologies in supply chains across the UK. It comes as a more practical approach to solving UK manufacturing and logistics challenges is needed, including the reduction of road congestion, improvement of customer experience, and bringing the UK closer to its net zero ambitions.

Tim Lawrence, Director of the Digital Supply Chain Hub said: “Manufacturers are facing unprecedented cost and risk pressures across all areas of their businesses, especially in their supply chains from increasing costs of energy, labour and logistics. There is growing demand from businesses to make supply chains more sustainable and this logistics project can play a key role in demonstrating the benefits of working together to achieve this.”

Leo Pickford, Head Of Business Change at Yusen Logistics said: “Our customers, who are

often operating on wafer thin margins, need to find ways to reduce costs and cut emissions.

Given that 25% of trucks still run empty, whilst a significant amount of operational planning is done at the last minute, logistics optimisation, particularly in Shared User Transport (SUT), is a key area where operational efficiency can be realised.”

“This project allows logistics companies like ours to collaborate and still compete in new and more efficient ways, with new business and governance models allowing logistics companies to work together to mutual advantage, reducing costs while working towards a more sustainable future.”

There will be an opportunity to learn more about this project through an observer gallery, being set up by Digital Catapult which will allow organisations to build on the work of this exciting pilot with regular showcases of the work to date. This will begin in April. If this is of interest, register on the Digital Supply Chain Hub site.